With the rapid advancement of modern technology, conductive fibers have become indispensable in various fields, including electronics, textiles, and aerospace. From anti-static workwear to high-end shielding materials for electronic products, their applications are widespread. In practical use, the layout of conductive fibers significantly influences the performance of the final products. Among the common layouts, the grid pattern and the inlaid strip pattern have attracted much attention. So, what are the characteristics of these two layouts, and which one will perform better in different scenarios? Let's take a closer look.

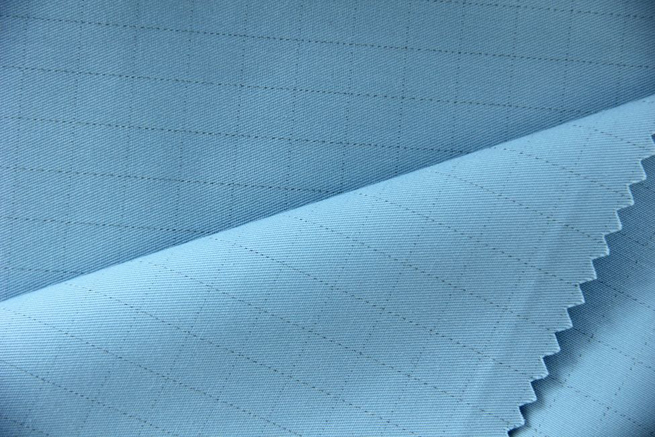

The grid pattern layout resembles a fine mesh at first glance. During the weaving process, conductive fibers interlace in both the warp and weft directions, forming regular small squares. This layout creates a complete and continuous conductive network on the plane, with conductive fibers connected in all directions, much like a well-connected transportation network, providing multiple paths for current flow.

In contrast, the inlaid strip pattern layout has a distinct appearance. It mainly involves embedding conductive fibers into the fabric along a single direction (usually the warp direction), creating parallel conductive strips. These strips are relatively independent, and there are fewer connections of conductive fibers perpendicular to the strips. The overall structure is more like a row of neatly aligned lines.

The grid pattern layout has a clear advantage in terms of conductivity. With conductive fibers distributed in both directions, the current can flow freely over a larger area. If a conductive fiber is damaged or has poor contact, the current can quickly find alternative paths through fibers in other directions, ensuring the uninterrupted flow of the entire conductive network. This excellent conductivity makes the grid pattern layout ideal for applications requiring efficient static electricity removal, as it can rapidly dissipate accumulated static charges and protect sensitive electronic components from damage.

The inlaid strip pattern layout, however, has relatively weaker conductivity. While it conducts current well along the direction of the fiber arrangement, its conductivity is notably limited in the perpendicular direction. If a single conductive fiber fails, it may prevent the timely removal of static electricity in the nearby area, affecting the overall electrostatic elimination effect. Nevertheless, in environments where the requirements for static protection are not extremely high, the inlaid strip pattern layout can still meet basic needs.

The complexity of the manufacturing process is a key factor differentiating these two layout technologies. The grid pattern layout is more complex to weave, as it requires precise control of the embedding of conductive fibers in both the warp and weft directions, demanding advanced weaving equipment and skilled operators. Additionally, due to the larger quantity of conductive fibers used, production losses are relatively high, driving up the production cost.

The inlaid strip pattern layout, on the other hand, has a simpler manufacturing process. It only requires embedding conductive fibers in one direction, resulting in higher production efficiency. With fewer conductive fibers used, the cost is also lower. This makes the inlaid strip pattern layout advantageous for large-scale production and applications where cost sensitivity is a key factor, particularly for safety workwear wholesale programs.

Conductive fibers are the unsung heroes of modern safety and performance, particularly in protective textiles where electrostatic discharge (ESD) control can mean the difference between safe operations and costly accidents. While grid and inlaid strip layouts are the two most prevalent configurations, their real-world performance varies drastically depending on the environment. Let's dive into their functional differences, with a focus on how they impact protective gear—from anti-static workwear to hazard zone uniforms.

The "grid pattern" isn't just a crisscross design—it's a 360° defensive network. Conductive fibers (often carbon or metal-coated polyester) are woven into both warp (lengthwise) and weft (crosswise) directions, creating overlapping junctions at intervals as tight as 1mm–5mm. This dense interconnectivity forms a "fail-safe" structure: even if one fiber breaks, adjacent junctions maintain conductivity across the entire fabric surface. For example, in arc-flash protective clothing, this redundancy ensures no single point of failure compromises ESD protection.

The "inlaid strip pattern", by contrast, is a linear system. Conductive fibers are integrated *only* along the warp direction, spaced 10mm–30mm apart, with minimal to no cross-connections. Think of it as parallel electrical lines running the length of the fabric. While this creates a streamlined structure, it leaves perpendicular gaps where conductivity drops significantly—up to 10x lower than the grid pattern in transverse measurements, according to textile engineering studies.

In high-stakes environments, conductivity isn't just a metric—it's a safety requirement.

- Grid Pattern: Its multi-directional design delivers consistent surface resistance (typically 10⁶–10⁹ Ω, per IEC 61340 standards), critical for rapid charge dissipation. In semiconductor cleanrooms, where a single static spark can destroy $10,000+ microchips, grid-patterned smocks have been shown to reduce ESD incidents by 72% compared to strip layouts (data from industry safety audits). For workers in explosive atmospheres (e.g., oil refineries), this layout ensures static charges disperse evenly across the garment, eliminating "hot spots" that could ignite fumes.

- Inlaid Strip Pattern: Surface resistance varies drastically by direction—performing well along the strips (10⁷–10¹⁰ Ω) but poorly across them (often exceeding 10¹¹ Ω). This makes it suitable only for low-risk scenarios, like general electronics assembly lines where components are less sensitive. A case study in a consumer electronics factory found that strip-patterned gloves reduced ESD events by 30% compared to non-conductive alternatives, but failed to meet strict aerospace ESD standards due to uneven charge distribution.

Manufacturing realities often dictate layout choice, especially for large-scale protective gear production:

- Grid Pattern: Weaving requires dual-axis precision, often using computerized jacquard looms, which increases setup costs by 20–30% compared to strip patterns. However, its durability offsets this: grid fabrics withstand 50+ industrial washes (per ISO 6330) without significant conductivity loss, making them cost-effective for long-term use in heavy industries.

- Inlaid Strip Pattern: Simpler single-direction weaving (using standard shuttle looms) cuts production time by 40%, with 15–20% lower material costs due to reduced conductive fiber usage. The tradeoff? Strips are prone to fraying at the edges, and conductivity drops by 30% after just 30 washes—making them better for short-term, low-wear applications (e.g., disposable cleanroom coveralls).

The decision hinges on three factors: risk level, usage duration, and compliance requirements.

For arc flash or explosive environments, the grid pattern is the clear choice. Its redundant conductivity prevents ESD hot spots and meets strict standards like NFPA 70E, ensuring safety in scenarios where even minor failures could have catastrophic consequences.

In semiconductor and microelectronics facilities, where sensitive components demand consistent protection, the grid pattern's 360° conductivity is irreplaceable. Its ability to disperse charges evenly across the entire fabric surface guards against costly damage from static discharge.

For general electronics assembly—where static risks are present but less severe—the inlaid strip pattern strikes a practical balance. It delivers basic ESD control at a lower cost, making it suitable for environments where high-end protection isn't strictly required.

Short-term or one-time use scenarios, such as event staff uniforms or temporary cleanroom coveralls, also benefit from the inlaid strip pattern. Its cost efficiency shines here, as the lower durability and simpler structure align with the limited lifespan of the gear.

Grid patterns reign supreme in high-risk, long-term protective applications, where reliability and compliance are non-negotiable. Inlaid strips, while cost-effective, are best reserved for low-risk, short-term use. For safety workwear manufacturers, selecting the appropriate conductive fiber layout is essential to balancing protection performance, regulatory compliance, and production efficiency.

As conductive fiber technology advances—with hybrid layouts (e.g., "strip-grid" combos) emerging—these boundaries may blur. But for now, understanding their strengths ensures your protective gear doesn't just meet standards, but exceeds them.tunities.

This is the last one.